How do you know if you have the right type of pressure switch? Even if you have the pressure switches, how to ensure it is working fine for your application process?

The moeller pressure switch is known as the core and vital device that is present in every electronic device and model. Pressure switches are also used in many applications in different industries and manufacturing processes.

What is a Pressure Switch?

It can be explained as a simple device that is activated by the pressure present in the pumps and line. This electromechanical device turns on/ off based on the circuit and signal given by the device.

What are the Key Components?

The diaphragm acts as the pressure detection element. The material it is made from is pliable which is sensitive to pressure thus making it ideal to be applied in switches.

The adjustment spring is used to vary the set or cut-out points. Some manufacturers use separate springs to control the set and cut-out points.

The ON/OFF lever activates the switch automatically or manually. The on/off lever also acts as the arm for deactivating the switch. This is used in the process of installation or if some maintenance needs to be done. Some of the switches have knobs rather than levers but both of them work the same.

Electrical contacts allow current from an external power source to pass through them when they touch.

Terminals connect the external power source to the contacts.

How Do the Pressure Switches Work?

The working principle of pressure switches is very simple, it can also be understood as working as a pressure sensor that measures the pressure in any process and provides the reading for further action.

Proper and accurate pressure monitoring is required in some applications for several reasons including safety.

There are different types of these switches available in the market and each comes with some qualities and benefits over the other. Their working will remain similar apart from some of their features that might vary with each application and its requirements.

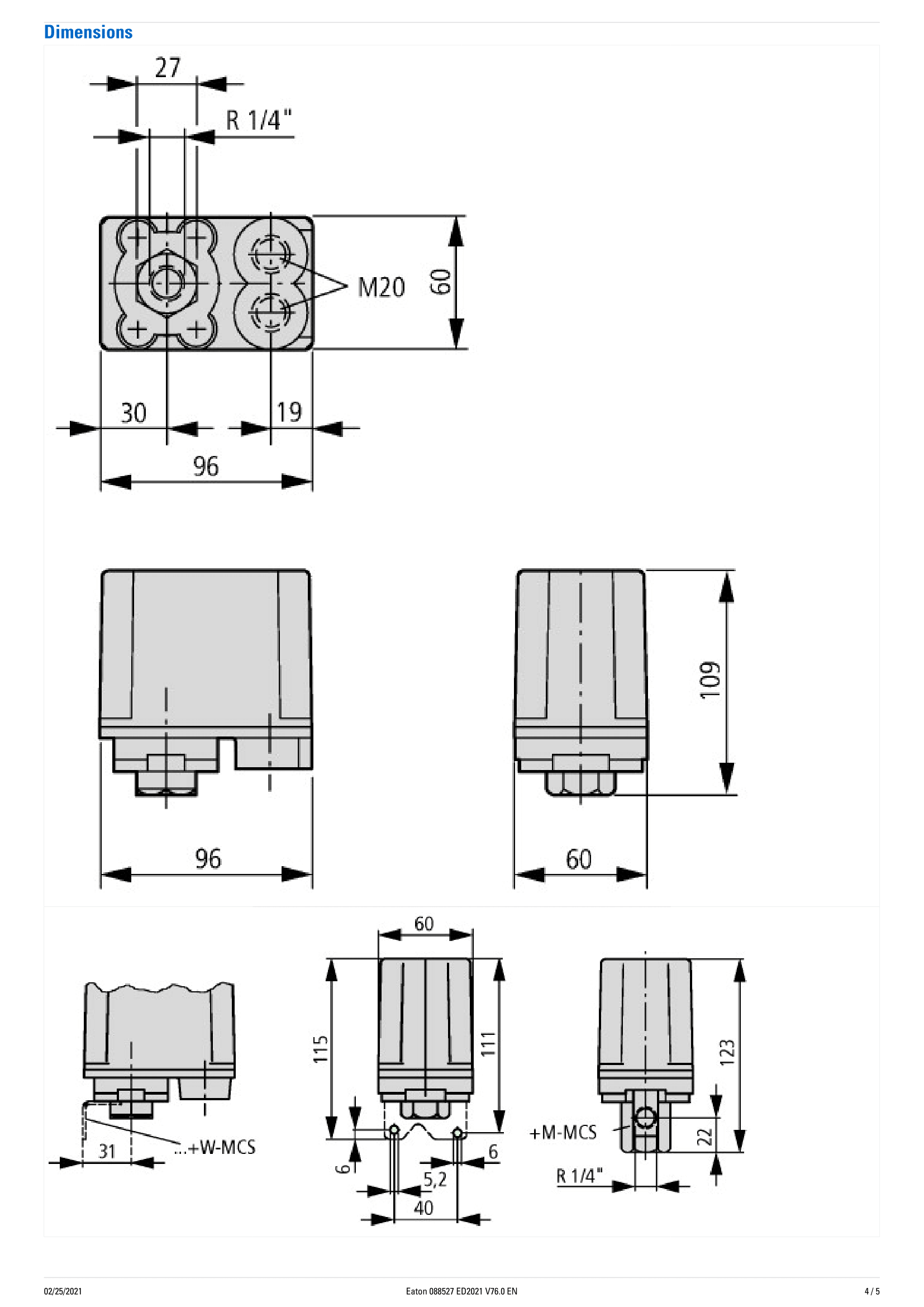

Let’s talk about how it’s working; we take the Moeller pressure switch MCS11 from Eaton as the example here. The pressure switch monitors and controls the demands of a machine that is constantly working under extreme conditions. It is one of the most reliable devices that provide accurate results in processes like oil and water pipelines. Industrial settings require a range of monitoring and controlling devices to ensure the process.

The pressure switches by a range of variably adjustable pressures.

The pressure switch price MCS11 has the protection certification IP 55 that is required for the insulating material and has an impact-resistant cover. When used this, it allows the person to save cost by minimizing the wiring as there is no need for the protective conductor.

The pressure ranges can be different for each process and selected up to 22 bars to match the requirements.

What are the Use Cases and Application Areas of Pressure Switches?

Companies and applications are always on the lookout for reliable pressure switches. For example, the Moeller MCS11 dies to provide reliable and accurate readings. The companies that have crucial processes rely upon and trust its performance. There can be several use cases for using pressure switch MCS 11 and some of these conditions are:

Prevent Clogging & Contamination

The clogging and contamination of the valve can put the threshold point at the wrong set.

Brake Line

This air helps in certain cases for example, in the emergency brake application. The application of emergency brakes increases pressure in the brake line system. The break application activates the switch.

Process Equipment

The manufacturing industries want to achieve their goals without issues and setbacks and to get this they want the right pressure switch for their equipment and process machinery. The pressure switch will help to ensure a stable fluid supply or gas flow for the unhindered working or the systems.

Pumping System

The pumps and motors are another use case of the Moeller pressure switch. It makes sure the level of water and the air pressure in pumps and pipes. The pressure switch activates and deactivates the pumps based on the setpoints.

How to Figure Out if the Air Pressure Switch is Good?

First, disconnect the power from the source and remove the cover of the switch.

Use pressure-producing sources to provide pressure in the next step. Place the ohmmeter leading to the loose wires. If the meter shows a reading of zero it means the air pressure is working fine.

There Are Some Points for Considerations Before Selecting Pressure Switch

These points can be some crucial aspects of your requirement and can hugely impact the application and affect the process if not done properly.

Make sure that the required setpoint is possible with the pressure switch

No matter what brand or make pressure switch you are using but it should be specific about the requirements and needs of that particular application. There are certain issues like set points, range, speed of travel, and the threshold, all of these can impact badly if not considered minutely.

Consider the compatibility

The compatibility can be a pain point in the future if not paid attention to start. The process fittings, pistons, O-rings, and diaphragms are some of the technical aspects of the pressure switch that need exact specifications. Incompatibility brings up problems like corrosion and safety concerns.

Mention the high temperatures and other working conditions

Read the datasheet very carefully and pay attention to the temperature specifications. The ambient environment of the application and extreme working temperatures can be different.

Check for additional needs and options

Look for some rare case scenarios like factory setpoint, tags, oxygen cleaning, special materials for housing/enclosure, wall/pipe mounting brackets, or specific certifications.

Fixed or adjustable deadband

The Deadband is the set point between the pressures which activate the switch. It comes in two varieties and can be selected based on the needs, fixed or adjustable.

What is the need to go through and check so many points?

Always select the right switch so it can handle the pressure effectively and normal operating pressure that can increase the pressure at any given time. Also, the pressure switch price can be another factor here you can control it also by looking at the given key points.

Conclusion

The Moeller pressure switch is ideal for use in several industries that require technicians or pressure switch operators.

Check other options to understand and get insight into Moeller MCS11. These are the pressure sensors that can change the way we see processes in the oil and gas sectors.

The pressure switches can successfully detect the changes in the physical, electrical, and chemical properties of the process.