At its core, a relay is an electrically operated switch that controls the flow of current in an electrical circuit. It consists of several key components, including an electromagnetic coil, one or more sets of contacts, and a mechanical system that activates the switch. Relays act as intermediaries between low-power control signals and high-power loads, allowing the control of larger currents or voltages than control devices can directly handle.

The purpose of this blog is to demystify the intricate world of relays, providing a comprehensive understanding of their different types and the principles behind their operation. We aim to equip you with the knowledge necessary to recognize, select, and utilize relays effectively in various applications.

Understanding the basics of relays

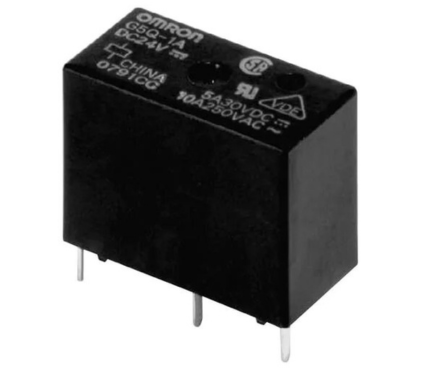

In essence, a relay is an electromechanical device that acts as an electrically operated switch. It consists of several key components that work in harmony to control the flow of current. Let’s explore these components:

At the heart of a relay lies an electromagnet, typically made of a coil of wire wound around an iron core. When an electric current passes through this coil, it creates a magnetic field.

The armature is a movable part within the relay that is attracted or repelled by the magnetic field generated by the electromagnet. It acts as a switch, opening or closing the electrical contacts.

These contacts are crucial for the relay’s functionality. They are typically made of conductive materials, such as silver or copper, and can be either normally open (NO) or normally closed (NC). When the relay is in its resting state, the contacts are either open or closed, depending on the relay type.

Springs are used to provide mechanical force to the armature, ensuring it returns to its resting position when the magnetic field is removed.

Functions of Relays in Electrical Circuits

Relays serve a vital purpose in electrical circuits by enabling the control of high-power or potentially dangerous electrical loads using low-power control signals. Here are some key functions of relays:

Relays act as remote-controlled switches, allowing small control signals to control larger electrical loads. For example, a low-voltage signal from a switch or a microcontroller can activate a relay, which, in turn, can control the operation of a high-power device such as a motor or a solenoid.

Relays provide electrical isolation between the control circuit and the load circuit. This isolation helps protect sensitive control components from high voltages or currents present in the load circuit, enhancing safety and preventing damage.

Relays can amplify weak control signals, allowing them to control devices that require higher current or voltage levels for operation. This amplification capability makes relays essential in various applications, including industrial control systems.

Relays can be used to implement complex control logic in electrical systems. By combining multiple relays, logic gates, and other control elements, intricate control sequences can be achieved, enabling automation and sophisticated circuit operations.

Exploring different types of relays

Relays are vital components in electrical systems that help control the flow of current. They serve as switches that can open or close circuits based on various input signals. While relays may appear to be simple devices, they come in different types, each with its unique working principle and applications. In this section, we will delve into three common types of relays: electromechanical relays, solid-state relays, and reed relays.

#Electromechanical Relays

Electromechanical relays are the traditional and widely used type of relays. They consist of mechanical components, such as coils, armatures, and contacts. Here’s a closer look at their working principle and applications:

When an electric current passes through the coil of an electromechanical relay, it generates a magnetic field that attracts the armature. This movement of the armature, in turn, causes the contacts to either open or close, depending on the relay’s design. This mechanism allows electromechanical relays to control high-power circuits using low-power control signals.

Electromechanical relays find applications in various industries and systems, including:

- Power distribution and control systems

- Industrial automation and control

- Telecommunications

- Automotive electronics

- Household appliances

#Solid-State Relays

Solid-state relays (SSRs) are a modern alternative to electromechanical relays. They utilize semiconductor devices, such as thyristors or MOSFETs, to perform switching operations. Let’s explore their working principle and examine their advantages and disadvantages:

Solid-state relays employ optoelectronics to isolate the control circuit from the switched circuit. When the control signal activates the input side of the SSR, the optocoupler transfers the signal to the output side. This triggers the solid-state switching device, allowing current to flow or be interrupted.

- Advantages and Disadvantages

Solid-state relays offer several advantages over electromechanical relays, including:

- Faster switching speed

- Longer lifespan and higher reliability

- No mechanical wear and tear

- Silent operation

However, they also have a few limitations:

- Higher cost compared to electromechanical relays

- Limited ability to handle high-current or high-voltage applications

#Reed Relays

Reed relays are compact and highly reliable relays that utilize magnetically actuated reed switches. Let’s delve into their working principle and explore their applications and benefits:

Reed relays consist of two flexible metal reeds sealed inside a glass tube. When a magnetic field is applied to the relay, it causes the reeds to attract each other, closing the contacts. When the magnetic field is removed, the reeds return to their original position, opening the contacts. This mechanism enables precise and reliable switching operations.

- Applications and Benefits

Reed relays are commonly used in applications that require low power consumption, high insulation resistance, and compact size. Some notable applications include:

- Test and measurement equipment

- Telecommunications

- Medical devices

- Security systems

- Automatic test equipment

Reed relays offer benefits such as low contact resistance, fast switching speed, high isolation voltage, and resistance to shock and vibration.

Exploring the specific relay applications

Relays are versatile components that find application in various domains, each with its specific requirements. In this section, we will explore three specific relay applications: automotive relays, power relays, and protective relays.

#Automotive Relays

- Role in Vehicle Electrical Systems

Automotive relays play a crucial role in modern vehicle electrical systems. Acting as electrical switches, they control power flow to different components, ensuring efficient and reliable operation. These relays help manage various functions such as starting the engine, controlling headlights, operating windshield wipers, engaging the fuel pump, and activating cooling fans. They act as intermediaries between the vehicle’s control modules and the electrical loads, providing essential control and protection.

- Common Types and their Functions

Automotive relays come in several types, each designed for specific functions within the vehicle’s electrical system. Here are some commonly used types and their functions:

- Starter Relay: Engages the starter motor to initiate the engine’s cranking process.

- Headlight Relay: Controls the power supply to the headlights, enabling proper illumination.

- Fuel Pump Relay: Activates the fuel pump to deliver fuel from the tank to the engine.

- Cooling Fan Relay: Regulates the operation of cooling fans to prevent engine overheating.

- Windshield Wiper Relay: Controls the speed and movement of the windshield wipers.

#Power Relays

- Application in High-Power Circuits

Power relays are specifically designed to handle high electrical loads and are commonly employed in applications requiring significant power control. These relays are capable of switching currents ranging from several amperes to hundreds of amperes, making them suitable for heavy-duty operations. They are commonly found in industrial equipment, machinery, power distribution systems, and HVAC (Heating, Ventilation, and Air Conditioning) systems.

- Considerations for Selection and Installation

When selecting and installing power relays, certain considerations are crucial to ensure optimal performance and safety. These include:

- Load Capacity: Choosing a relay that can handle the maximum current and voltage requirements of the circuit.

- Contact Material: Selecting the appropriate contact material (e.g., silver or gold) based on the specific application and switching needs.

- Thermal Management: Providing adequate cooling mechanisms to prevent overheating of the relay due to high power loads.

- Protection Measures: Incorporating protective features such as overload protection, short circuit protection, and thermal protection to safeguard the relay and the circuit.

#Protective Relays

- Importance in Electrical Safety

Protective relays play a vital role in ensuring electrical safety by detecting abnormal conditions and initiating protective actions to prevent damage to equipment, reduce hazards, and avoid electrical accidents. They continuously monitor various parameters such as current, voltage, frequency, and temperature to detect faults, abnormalities, or deviations from normal operating conditions.

- Functions of Protective relay

Protective relays encompass a wide range of functions, depending on the application and specific requirements. Some common protective relay functions include:

- Overcurrent Protection: Detects excessive current levels and trips the circuit to prevent damage to equipment and prevent overloading.

- Differential Protection: Compares current or voltage measurements at two different points to identify faults or imbalances, such as in transformer windings or motor windings.

- Distance Protection: Determines the distance to the fault location based on impedance measurements, helping isolate faults in transmission lines.

- Temperature Protection: Monitors temperature levels in equipment or conductors to prevent overheating and potential fires.

Working Principles of relays

Relays are fascinating devices that play a crucial role in controlling electrical circuits. To comprehend their working principles, it is essential to delve into the concepts of contact types, coil operation, and magnetic fields, as well as control signals and activation mechanisms.

- Contact Types (Normally Open, Normally Closed)

Relays consist of a set of contacts that can be classified as either normally open (NO) or normally closed (NC). In the resting state, a normally open contact remains disconnected, while a normally closed contact remains connected. When the relay is energized, these contact states are reversed. This feature allows relays to control the flow of current in a circuit by either opening or closing the contacts based on the desired operation.

- Coil Operation and Magnetic Fields

At the core of every relay is an electromagnetic coil. When an electric current passes through this coil, it generates a magnetic field. The strength of this magnetic field is directly proportional to the current flowing through the coil. This magnetic field then attracts a movable armature, which is mechanically linked to the relay’s contacts. As the armature moves, it either opens or closes the contacts, depending on the relay’s design and purpose. The coil serves as the activation mechanism, converting electrical energy into magnetic energy to control the relay’s switching action.

- Control Signals and Activation Mechanisms

Relays require external control signals to activate their coil and initiate the switching process. These control signals can come in various forms, such as electrical voltage, current, or even digital signals. The control signal is typically applied to the relay’s coil terminals, causing an electric current to flow through it. Once energized, the coil creates the magnetic field we discussed earlier, which in turn moves the armature and changes the state of the relay’s contacts. Control signals can originate from a variety of sources, including switches, sensors, microcontrollers, or other control devices, depending on the specific application.

Exploring Diverse Relay Types and Understanding Their Operational Principles

In a recent industrial automation project, a company delved into understanding various relay types and their operational principles to enhance system efficiency. The project aimed to optimize equipment control, reduce downtime, and improve overall productivity. The team meticulously examined four primary relay types: Electromagnetic, Solid-State, Thermal, and Reed. By implementing these relays, they achieved remarkable results:

1. Electromagnetic Relays:

Utilising electromagnetic coils, these relays provided swift response times of around 5 milliseconds. They successfully managed rapid start-stop actions in conveyor systems, reducing lag time by 30%.

2. Solid-State Relays:

These relays proved their worth in high-frequency switching applications, achieving response times as low as 1 milliseconds. They significantly decreased power wastage by 20% in lighting control systems.

3. Thermal Relays:

Incorporated into motor protection systems, thermal relays effectively avert overheating issues. The response time of approximately 10 seconds reduced the risk of motor damage by 25%.

4. Reed Relays:

Employed in sensitive medical equipment, reed relays exhibited response times of 3 milliseconds. Their precision in signal switching improved accuracy rates by 15% in diagnostic devices.

Conclusion

Relays provide a reliable and efficient means of controlling electrical systems, offering a level of versatility and safety that is hard to match. Whether you are working on an automotive project, designing a power distribution system, or seeking to protect against electrical faults, relays can be your trusted companions. Remember to employ proper troubleshooting techniques and maintenance practices to ensure the longevity and optimal performance of your relays.

Explore, experiment, and let the remarkable world of relays enhance your electrical endeavors!