A MEMS thermal sensor is referred to as a thermocouple or temperature detector. It takes the temperature dimension. This dimension analysis is in a readable shape that may be deciphered via the electric signal.

What are the capabilities of a temperature sensor?

The MEMS temperature sensors are used to measure the warmth and temperature of the surroundings or any item. It is available in primary sorts which can be contact and no contact temperature sensors.

The contact sensors are those that consist of thermocouples and thermistors. This sensor works by being in direct contact with the object its measures. The second kind is the non-contact temperature sensors, which measure the temperature that is emitted by means of the warmth supply. Non-contact temperature sensors are by and large utilized in risky conditions. These have a nice use in such environments wherein contact from the warmth supply may be risky like nuclear or thermal electricity plants.

How does MEMS temperature sensor work?

The operating principle of temperature sensors is primarily based on the voltage in the diode and different terminals. If the temperature increases then the voltage is also additionally increased. It is generally accompanied by means of lower voltage. The reduced voltage runs among the transistor terminals and the emitter of the diode.

This function has a magnetic and very long tensile cord, this is stretched and the ends of this cord are constant to an extraordinary type of metal. It is connected in such a manner that if there’s an increase in the temperature it will immediately affect the length of the cord so the frequency of vibration may even increase with the intention to be proven into the readings.

The extraordinary material of the terminal generally is aluminum (it has a bigger expectancy of thermal growth than different substances together with steel). As the temperature sign is transformed into frequency, the equal read-out unit that’s used for different vibrating cord sensors also can be used for tracking temperature additionally.

The increase in temperature is sensed via means of the in particular constructed in the vibrating cord sensor and is transformed to an electrical sign that’s transmitted as a frequency to the read-out unit.

Shop Now

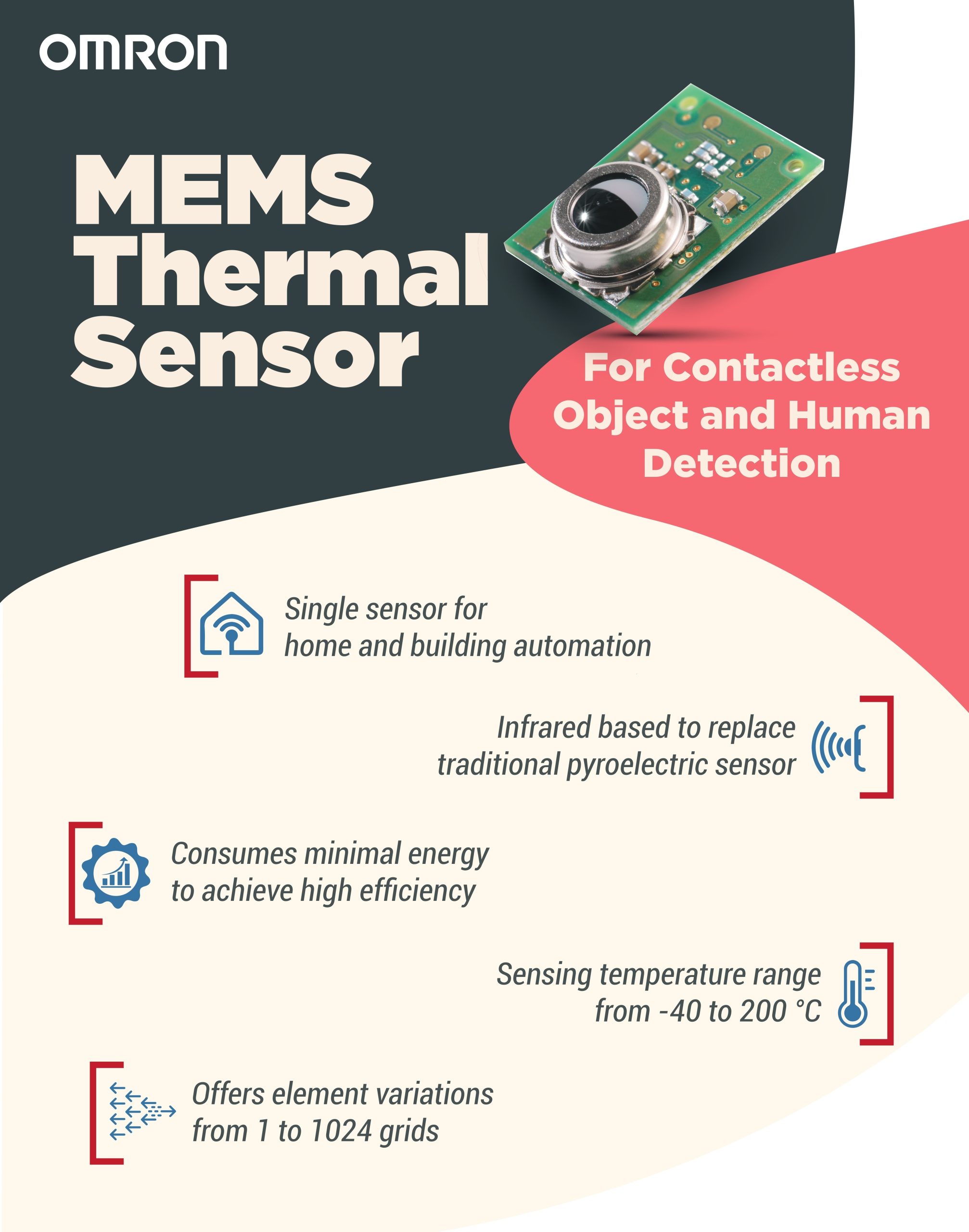

Features of MEMS Thermal Sensor

MEMS Thermal sensor collection is a module product that permits reference to handiest one connector, smart silicon lens, MEMS thermopile sensor, devoted analog circuit, and good judgment circuit for conversion into virtual temperature statistics on a small circuit board. Described underneath is an outline of dimension via way of means of the thermal sensor:

- The silicon lens concentrates the radiant warmth (some distance infrared rays) generated via means of the item at the thermopile sensor in the module.

- The focused radiant warmth (some distance infrared rays) generates an electromotive pressure via the thermopile sensor.

- The electromotive pressure fee and inner temperature sensor fee are measured and the measured fee (item temperature) is calculated via means of interpolation; the usage of the integrated research desk is primarily based totally on one’s values.

- The measured fee is loaded from an upstream gadget through the I2C bus.

- A MEMS sensor affords the handy capabilities to be had with another sensor line; however, you don’t want to problem yourself with area constraints. MEMS makes use of very compact micro system additives so small that every sensor can be shaped into the palm of your hand. While electrolytic sensors have a lot better accuracy, a number of them may be in contact with temperature.

These sensors are remarkable answers to programs that don’t call for the very best accuracy together with business automation, platform leveling, function control, and pitch and roll dimension.

Advantages of temperature sensor

MEMS generation does have a few benefits of its own. MEMS sensors offer handy capabilities to be had with each different sensor line with no area constraints. In addition, MEMS uses very compact micro system additives so tiny. That every MEMS sensor can effortlessly be shaped into the palm of your hand. This is due to the fact the sensors want you to face up to a few severe temperatures starting from 40º to +85ºC. And, this seal permits the sensors to be submerged into shallow water for brief periods. Letting them reveal the offshore and subsea pitch and roll programs. Other electrolytic sensors may have better accuracy however there is frequently greater contact to temperature.

Another gain of those MEMS sensors is their surprise and vibrations resistance. So, those sensors aren’t for use in particularly stunning situations together with army programs. However, they could maintain as much as business measurements and control, grilling gadgets, and a few geotechnical tracking.

Conclusion

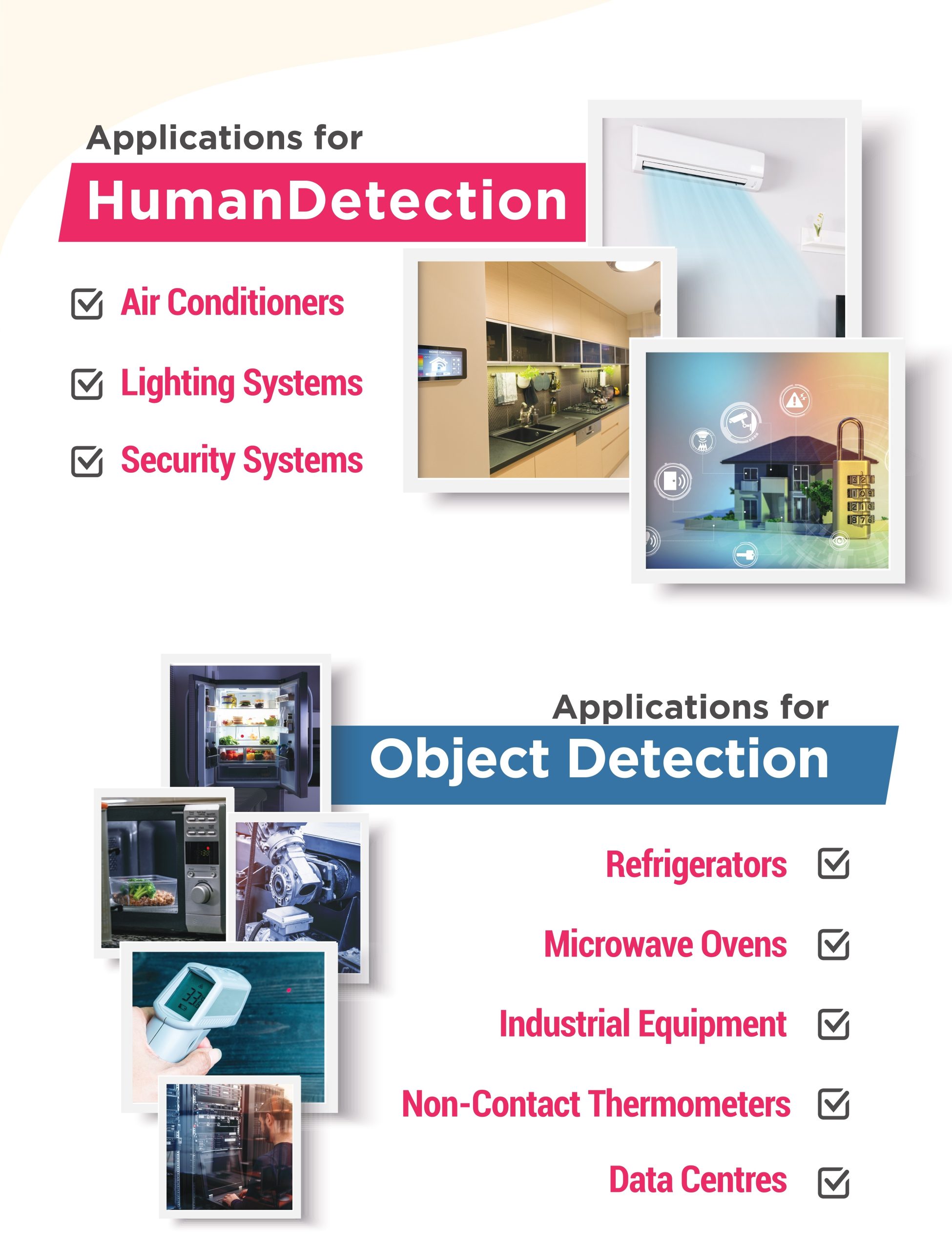

MEMS Thermal sensor is an infrared temperature sensor that can measure floor temperature without contacting. Via means of receiving radiant warmth from the item with thermopile element(s).

To aid embedded programs, OMRON has carried out thermopile element(s) and ASIC into one package deal of MEMS Thermal sensor. The usage of its specific MEMS generation, materializing an ultra-small module. The digital output of temperature statistics detected via means of the MEMS Thermal sensor via I2C communications can lessen. Each processing load of the master-quit microcontroller and the improvement period. With its non-contact dimension of goal floor temperature, MEMS Thermal sensors can make contributions to power saving, higher amenity. Productiveness development through detecting a human or an item or strange heat technology of the device in numerous locations inclusive of a home, building, and/or factory.