The silicone material is known for its effectiveness and versatility in several applications. It is one of the most commonly used materials in electronic devices and processes.

Similarly, the designers and manufacturers use thermally conductive silicone pads for various reasons.

The electrically conductive pads are made of silicone and the most useful thing is that they can be manufactured in a wide array of shapes and sizes.

Best Offer Available

You can also find them in various thicknesses and compression levels. This helps in addition to enabling the requirement of different designs and processes, also the silicone thermal pads provide beneficial electrical isolation properties.

Let’s ponder deeper into this topic for today and find out more!

What are Thermal Interface Materials?

Thermal interface materials or thermal management solutions are quite important in electronic devices, the TIMs have become quite powerful and dissipate heat and the lack of good thermal materials will impact overall thermal management and performance.

There are several types of materials that are useful in removing heat by leading it away from certain sensitive areas.

These materials are known as thermal interface materials and they fulfill the purpose to lead the heat away that is generated by the electrical and mechanical components.

The TIM materials are connected to the heat sink, it works like a dumpster for heat as metal like aluminum, copper, ceramic, etc, helps to absorb it.

The heat sinks create a deep ridge that makes tiny air gaps in between the ridges. Which is an ideal thing to dissipate the heat accumulated into the heat sinks.

The thermal interface materials provide a very common yet useful solution in any machinery and electrical device.

One such material is thermally conductive silicone pads and these are used to make sure those uneven, bendy, and rough surfaces also get enough and appropriate thermal conduction.

The electrically conductive pads are also serving as gap fillers which are cut into specific sizes and fitted between the gaps of components like from heat generated components and the heat sink.

The gap fillers create a tight-fitting connection with materials that are thermally conductive and fill the blank spaces.

What is Excessive Heat and Why Do We Need to Get Rid Of It?

All electronic devices run on electricity and the internal circuits are made of several materials that create the path for electricity flow that reaches into the different components making them act and control.

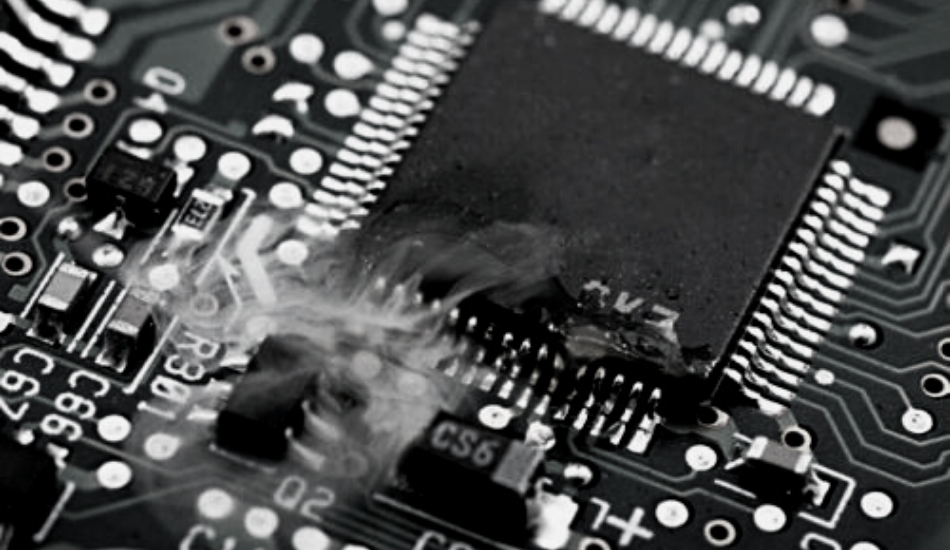

Now we all know that any device running on electricity gets heated after running for a while. They must get time to cool down if cooling time is not given it will make the device slower and damaged.

If this continues for longer, it might also blow up the device, getting everyone in danger.

This scenario of a device getting hot is known as excessive heat generation and getting rid of it is the only option to protect the device and ensure its good performance.

You can find different materials being deployed to cut down the heat or remove excessive heat from more sensitive components to other areas like a heat sink through the electrically conductive pads or other thermal management materials.

Why Devices Need Thermal Solution

Modern and contemporary electronics have become smarter and come with an integrated electronic system with a higher capacity for challenging and complex processing.

Also, keep in mind that modern electronics have become quite smaller and more compact with increased capacity to function. By doing so they create more heat and efficient control and getting it removed has become necessary and crucial.

When the thermal solution is done effectively it helps enhance the performance and prevents heat-related accidents like fire and circuit failure in the device.

Excessive heat is the main reason for reliability drops and product performance failure. The limited design advancement has the potential of degrading over time.

How Electrically Conductive Pads Dissipate The Heat?

![]()

The electrically conductive pads are one of the methods among various to remove the heat. To know this first understand how it works and what are its characteristics.

The electrically conductive pads are thermally conductive and this refers to their ability to successfully carry the heat from one area to another.

Thermally conductive silicone pads are fitted between two components. One generates the heat as it functions and the second one is a heat sink.

It connects the two components ensuring heat dissipation from the heat source to the heat sink that prevents overheating.

Thermal pads are very good due to their excellent conduction. The silicone pads are also used as very good gap fillers and this process is known as wet-out during the assembling and is used by many manufacturers and designers as it is a better option than any other materials.

Most other materials are quite stiff to place between uneven and rugged surfaces. Also, silicones are much better thermal conductors.

What Are The Application Areas of Electrically Conductive Pads?

We have quite a clear image of electrically conductive pads but it is used in other processes and applications apart from just electronic devices. Some of these processes are:

- Heat sink bonding process

- Wire tacking or assembling process

- Magnet bonding in electric motors

- Bonding LED touch screens and keypads

- Bonding surface mount devices to PCBs

- Potting and encapsulation of electronic components

- Component rigidising

- Sensor bonding

- Coil winding

- Applications within batteries and battery packs

How Is Silicone Thermal Pads Advantageous?

You can find that thermally conductive silicone pads can be used in innovative ways. Their versatility makes them beneficial in addressing and dissipating heat across many applications. They offer some common benefits, which include:

By using silicone pads you choose a very clean application process without the mess.

Silicone is a material that is very easy to work with. This includes its usefulness in the die-cut process into specific sizes.

Thermal pads come in other materials also apart from silicone and this is helpful as some of the applications might need some other interface. Also for some custom applications silicone might not be the best.

Thermal pads are reusable which makes them cost-effective and pre-cut sizes are easy to fit. During the assembling process saving the manufacturing time.

We all know the benefits of having a good thermal interface material and electrically conductive pads do extend. The lifespan of components and devices.

The application process of an electrically conductive pad is quick and easy. Just peel the lining layer and stick it to the surface.

This is not only a good thermal conductor but can fill bigger or smaller gaps between components. Having gap fillers enable the device to withstand shock and vibration making your electrical device robust and rugged for extreme usage.

Thermal Pads are the best choice as they can conform to some of the most uneven and irregular surfaces. The silicone material is manageable and softer and pliable at high temperatures.

Also, you just need small pressure to activate the adhesion, no need to use any external equipment to apply it.

Conclusion

Finally, in the end, thermally conductive silicone pads have become useful in current devices not only in electronics.

There are more to the conductive silicone pads and we are proud to say that we are the authorized and leading figure in the distribution market of silicone thermal pads in India.

You can find more information on our website or simply just connect with us!