Monitoring of dangerous gasses in the ambient air might be difficult but it is extremely essential to ensure a safe working environment and surroundings for workers. An excessive amount of oxygen or poisonous gas in the atmosphere like hydrogen sulfide, chlorine, or ammonia, can pose the risk of life to working crew and devices.

Why are oxygen gas sensors required?

Industrial poisonous gas and oxygen gas detectors screen the presence of gasses and send the alert if risky to detect the dangerous level of gasses. Gas detectors are normally hooked up wherein there are chances for a gas leak, and wherein risky gas levels pose an instantaneous threat to people or devices. Toxic gas detectors are broadly utilized by industries that include gas and oil, medical, mining, nuclear, construction, food and beverage, and commercial.

How does gas detectors work?

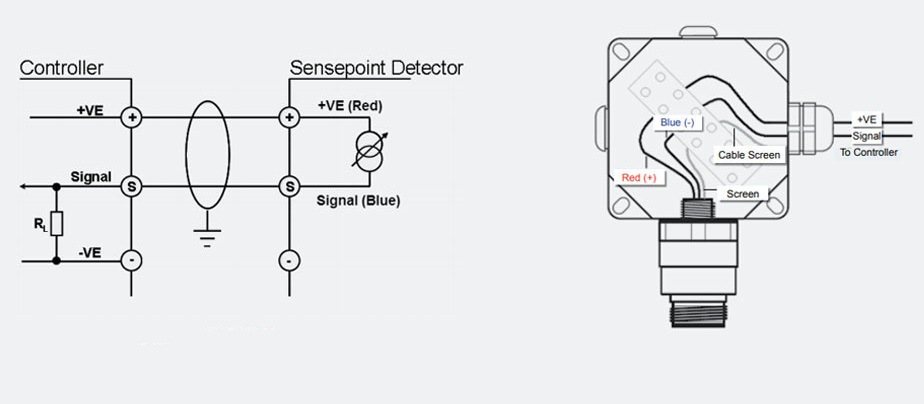

Gas detectors are programmed with a pre-set level of required gasses in the surroundings. Those are adjusted based on the kind and attention of gas being monitored. A sensor in the poisonous gas detector reads the gas level. And once they go above or fall under the desired level, the alarm system gets activated. Sensors are crafted from electrochemical cells, and the alarm may be visible or audible. Readings may be sent through the digital signal or analog signal to the control unit. And alarms can actuate relays for the operation of alarm protection gadgets inclusive of horns, fans, valves, etc.

What are the uses of the O2 gas sensor?

The average level of oxygen in the environment should range between 19-23%. If it goes below 19% people will start feeling drowsiness, nausea, and elevated heart rate. In confined spaces, a decrease in oxygen can result from dilution due to nitrogen, helium. And different inert gases are typically utilized in the laboratory, pharmaceutical, or semiconductor programs.

The extremely low oxygen level can result in death also. Industrial oxygen gas detectors protect from those risks with the help of tracking oxygen levels and triggering an alarm.

Prevention of workplace dangers with O2 gas detectors

Some poisonous gases have a very pungent and sharp odor whereas other gasses like carbon dioxide lack the smell that makes it hard to be detected without sensors or detectors. The presence of poisonous gases at an excessive level offers extreme health and protection risks, which include explosion, fire, and contamination or death.

Oxygen gas sensors assist with the aid of using tracking capacity leakage areas for dangerous gas levels. They are typically used on oil rigs and in chemical plants and production centers. Wherein poisonous fluids and gases are being manufactured and processed.

Selecting the right gas detector for your application

There are various things to keep in mind while looking for an ideal gas sensor like the points mentioned below:

Reliability: This is possibly the most essential due to the fact oxygen detectors that regularly malfunction or have a brief product existence can put the work at risk.

Features & Usability: You need to pick an oxygen gas detector that is durable, easy to install, and might resist the situations of working surroundings. The tool has to additionally match the recording necessities and be clean to hold and calibrate.

Reading Sensitivity & Accuracy: Some gas detection programs require a better level of sensitivity than others, so make sure the oxygen gas detectors can check in readings inside the desired range.

Alarm Response Time: When it involves oxygen or poisonous gas attaining a risky level, each second counts. Make sure the gas detector you pick has a reaction time that lets you sufficient time to react and treat the issue.

Sensitivity to Environmental Factors: Depending on the working surroundings, a gas detector is probably exposed to heat, moisture, humidity, or different gases. Those elements must affect the reliability of the readings and consequences furnished with the aid of using your poisonous gas detector.

Some other factors to consider before choosing the oxygen gas detectors:

- Area classification

- Enclosure type

- Output option

- Gas type

- The range of sensor

- The location of sensor

Application areas of gas sensors

Medical

In the medical sector, oxygen gas sensors are one of the most common components. They are used in anesthetic instruments, respirators, and oxygen enriches.

Biotechnology

The oxygen gas detector is also very useful in the biotechnology industry for devices like incubators.

Food industry

In food and beverages, it is needed for refrigeration, preservation.

Safety

It is required in air conditioners, oxygen detectors, and fire detectors to be used for safety reasons.

Conclusion

Oxygen gas detectors that include a sensor able to detect flammable gas might be set to discover one precise gas. Many gases may be dangerous to our health because of their toxicity. Understanding the fundamentals of why we discover gases will assist you in appreciating why. We have to use this protection device effectively and it’s far from installation to discover the suitable gas in every given scenario.