In recent months, the electric vehicle (EV) industry has been under heightened scrutiny, prompting regulatory authorities and industry thought leaders to emphasize the necessity of stronger safety measures and checks, especially in the domain of two-wheelers. This renewed focus has sparked the interest of industry stakeholders in exploring innovative options and configurations for the electronic components used within the vehicle’s battery charging ecosystem.

Best Offer Available

At the heart of electric vehicles lies the EV battery pack, comprising multiple battery cells and a critical component known as the Battery Management System (BMS). The BMS plays a pivotal role in managing rechargeable batteries, ensuring their efficient and safe operation. However, within this confined space, the circuit board of the BMS, housing numerous electronic components, can contribute to elevated ambient temperatures within the battery pack. Managing this heat becomes imperative for ensuring vehicle safety.

In light of recent incidents and emerging technological challenges, it is essential to address the heat management issues inside the battery pack and enhance the cooling mechanisms. One effective approach to achieve this is by incorporating superior electronic components that generate less heat, thereby reducing the reliance on additional cooling accessories.

While Direct Current (DC) Power Relays are commonly used in electric and hybrid four-wheelers, it’s time for the burgeoning EV two-wheeler industry to also leverage DC power relays across various applications. Despite the smaller battery space in two-wheelers compared to four-wheelers, DC power relays can adapt to these more compact environments.

Best Offer Available

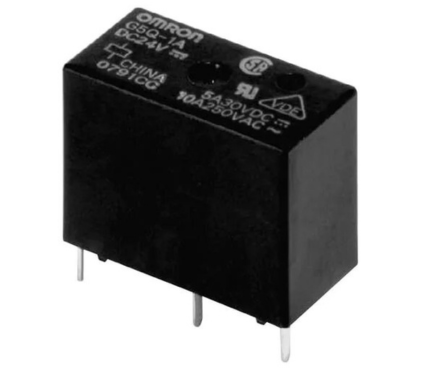

Omron’s Automotive DC Power Relays offer numerous advantages that align perfectly with the EV industry’s evolving needs. Some of these advantages include:

- Compact Design: Omron’s DC Power Relays are exceptionally compact, occupying 70% less volume compared to conventional solutions like contactors. This compactness is a significant asset when space is at a premium.

- Superior Ambient Temperature Tolerance: These relays are designed to withstand high operating temperatures, capable of handling up to 85 degrees Celsius. This resilience is crucial for ensuring the reliability and safety of the EV’s battery charging system.

- Power Efficiency: Omron’s relays are engineered for power efficiency, consuming 30% less power than their traditional counterparts. This not only contributes to energy savings but also reduces heat generation.

- Reduced Operating Noise: Noise levels are minimized with Omron’s DC Power Relays, offering a 50% reduction in operating noise compared to alternatives. This ensures a quieter and more pleasant user experience.

- Innovative Arc Control: Omron’s relays feature gas-cooled arc technology, using high-pressure inert gas within hermetically sealed chambers to extinguish arcs more rapidly and enhance heat conduction due to the exceptional thermal conductivity of the gases. Additionally, magnetic arc control employs permanent magnets to push the arc away from the contact, based on Fleming’s left-hand rule.

In summary, the adoption of electric vehicles is actively encouraged by governments worldwide to protect the environment and reduce emissions. Therefore, it is paramount to identify and integrate technologies that not only promote the widespread adoption of EVs but also enhance their safety and efficiency. Omron’s Automotive DC Power Relays stand out as a reliable and technologically advanced solution, addressing the evolving needs of the EV industry and contributing to a more sustainable and eco-friendly future.