In industries like automotive, construction, electronics, and general manufacturing, achieving a strong and reliable bond is essential. Whether you are attaching a car emblem, assembling an electronic panel, or installing glass signage in a building, the quality of the adhesive you use can make or break the project.

Traditional mechanical fasteners like screws, bolts, or rivets often add weight, require drilling, and can compromise aesthetics. VHB (Very High Bond) Tape offers a modern alternative that combines strength, flexibility, and ease of use.

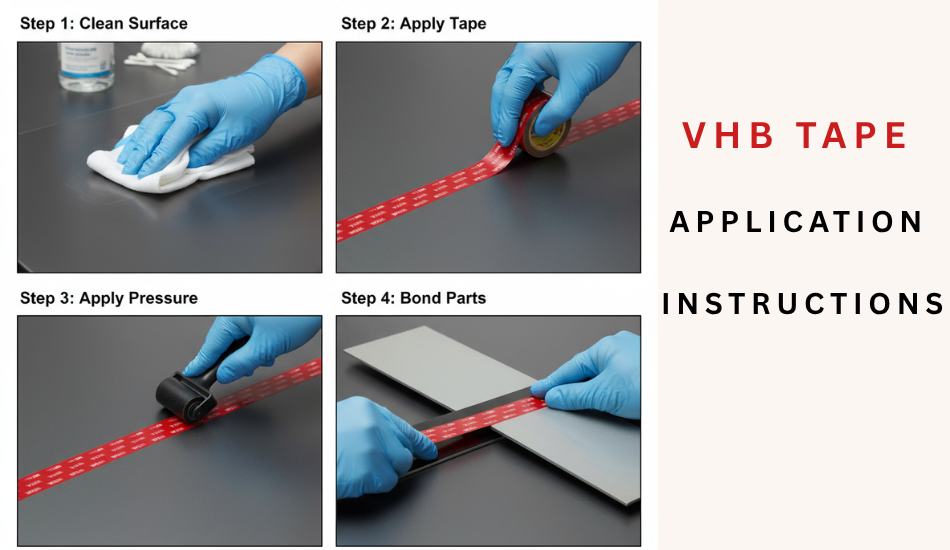

While VHB tape is widely known for its simplicity, proper application is key to unlocking its full potential. Surface preparation, correct application techniques, pressure, and environmental considerations all play a crucial role in achieving maximum adhesion and durability.

This guide provides practical, step-by-step tips to help both professionals and DIY enthusiasts get the best results when using VHB tape, ensuring long-lasting, reliable bonds across a wide range of applications.

What is VHB Tape?

VHB tape is a double-sided acrylic foam tape engineered for high-strength, long-term bonding. Unlike regular tapes, VHB uses a unique acrylic adhesive that can conform to surfaces, absorb vibrations, and resist environmental factors such as UV exposure, moisture, and temperature fluctuations. This makes it ideal for industrial and outdoor use.

Its key advantages include:

- Strong adhesion to metals, glass, plastics, and composites.

- Vibration resistance, making it suitable for automotive and machinery applications.

- Weatherproof and UV resistant, allowing outdoor use without degradation.

- Elimination of mechanical fasteners in many applications, reducing installation time and improving aesthetics.

Applications of VHB tape are broad. In the automotive industry, it is used for mounting trims, emblems, spoilers, and panels. In electronics, it bonds enclosures, display screens, and components. Construction professionals use it for glass panels, signage, and metal joining. Its versatility makes it a preferred solution for both critical industrial tasks and high-end household projects.

Preparing Surfaces for VHB Tape

The foundation of a strong VHB bond is proper surface preparation. Even the best tape cannot adhere effectively to dirty, greasy, or uneven surfaces.

- Clean the surface thoroughly using isopropyl alcohol or a suitable cleaner to remove dust, oils, and grease.

- Dry completely. Moisture can prevent the adhesive from forming a proper bond.

- Roughen smooth or glossy surfaces lightly if needed, using fine sandpaper, to improve grip.

- For low-energy plastics or treated surfaces, consider using a surface primer or activator to enhance adhesion.

Taking the time to prepare surfaces correctly can dramatically increase the tape’s holding power, especially for structural or load-bearing applications. Improperly prepared surfaces are one of the most common causes of bond failure.

Cutting and Applying VHB Tape

Correct cutting and placement are crucial for a professional finish. Start by measuring and cutting the tape to the required length using scissors or a utility knife. Remove the liner carefully, avoiding contact with the adhesive side.

Alignment is key. Place the tape precisely where it is needed and press firmly along the entire length to ensure even contact. Applying uniform pressure prevents air bubbles and gaps, which can weaken adhesion or reduce longevity.

For long surfaces, it may help to work from one end to the other gradually, pressing down as you go. For curved or irregular surfaces, carefully conform the tape to the shape to ensure full contact. Correct placement at this stage avoids adjustments later, which could compromise the bond.

Applying Pressure for Maximum Bond

VHB tape relies on pressure activation to perform optimally. Applying firm pressure ensures molecular-level contact between the adhesive and the substrate. The recommended pressure is roughly 1–2 kg/cm² along the tape’s length. This can be achieved using a roller, squeegee, or firm hand pressure.

For larger or structural applications, a roller is preferred, as it ensures even pressure across the entire surface. Avoid disturbing the surfaces while the adhesive cures, as movement can cause misalignment or weaken the bond. Proper pressure not only increases immediate adhesion but also improves long-term durability, especially in outdoor or high-stress conditions.

Environmental Considerations

Temperature, humidity, and surface conditions all affect VHB tape performance. The ideal application temperature is between 15°C and 38°C (60°F–100°F). Surfaces should be dry, clean, and free from frost. While VHB tape is UV and weather resistant, initial curing benefits from moderate, dry conditions.

Avoid applying tape to surfaces exposed to extreme cold or heat immediately after installation. For outdoor installations, consider waiting for a period of stable, dry weather to achieve the best bond. Temperature fluctuations during the curing period can influence the adhesive’s molecular bonding and long-term performance.

Curing Time and Handling

VHB tape forms an instant initial bond, but full strength develops over approximately 72 hours. During this period, it is important to avoid putting mechanical stress, weight, or vibration on the bonded surfaces.

For thicker tape or structural applications, extended curing time may be necessary. Factors such as ambient temperature, surface type, and applied pressure affect how quickly the adhesive reaches maximum strength. Patience during this phase ensures long-term durability and safety, particularly in automotive, industrial, and structural projects.

Common Mistakes to Avoid

Several common mistakes can compromise VHB tape performance:

- Applying the tape on dirty, oily, or wet surfaces.

- Not applying enough pressure during installation.

- Misalignment during placement, leading to gaps or uneven adhesion.

- Using the bond for heavy loads immediately, before full curing.

- Exceeding temperature or chemical limits specified by the manufacturer.

Avoiding these errors ensures that VHB tape achieves its full strength and longevity, preventing premature failures and costly rework.

Benefits of Using VHB Tape Correctly

Properly applied VHB tape provides strong, durable, and aesthetically clean bonds without screws or rivets. It reduces installation time and labor costs and provides vibration and shock absorption, which is critical in automotive, machinery, and electronics applications.

VHB tape also offers long-term resistance to UV, weather, and chemicals, making it suitable for outdoor environments. Its ability to bond multiple surfaces—metal, plastic, glass, and composites—enhances versatility and efficiency in industrial applications. For businesses, using VHB tape correctly improves product quality, reduces defects, and ensures reliable performance.

Advanced Tips and Best Practices

For maximum results, consider these advanced tips:

- Use primer or surface activator for low-energy plastics.

- Cut the tape slightly longer than needed for precise trimming after placement.

- Store tape in a cool, dry place to maintain adhesive quality.

- In critical structural applications, consider pairing VHB tape with mechanical fasteners for added safety.

- Avoid stretching the tape excessively during application, as this can cause gaps or reduced adhesion.

Following these best practices helps unlock the full potential of VHB tape, ensuring optimal bond strength, longevity, and reliability.

Practical Examples of VHB Tape in Action

- Automotive Industry: Mounting trims, spoilers, mirrors, and emblems without drilling holes or using screws. VHB tape absorbs vibrations from the engine and road, maintaining a secure bond over time.

- Electronics Assembly: Bonding panels, enclosures, and LED components without adhesives that may leave residues or damage sensitive surfaces.

- Construction Applications: Installing glass panels, metal signage, and decorative elements, providing clean finishes without mechanical fasteners.

By following proper techniques, VHB tape can replace screws, rivets, and even some welding applications, saving time, reducing labor costs, and enhancing aesthetics.

Conclusion

VHB tape is a versatile, high-strength adhesive solution that offers unmatched convenience and performance. Achieving the best results requires attention to surface preparation, careful application, proper pressure, and environmental awareness. When used correctly, VHB tape delivers strong, durable, and clean bonds across automotive, electronics, construction, and industrial applications.

Whether you are a professional installer or a DIY enthusiast, understanding and following these steps ensures reliable, long-lasting results. By investing time in proper application, you can fully leverage VHB tape’s benefits: saving labor, reducing maintenance, and achieving strong, aesthetically pleasing, and durable bonds every time.