Description

Best Thermal Pad for Heat Sink

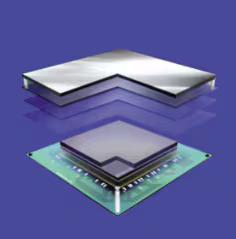

The 3M™ Thermally Conductive Acrylic Interface Pad 5571 is a thermal interface material designed to provide an effective heat transfer path from heat-generating components to a cooling device such as an aluminum plate or heat sink. It helps improve device reliability and support longer component lifespan.

3M™ 5571 is a single-layer, thermally conductive acrylic interface pad. It is made from a slightly tacky acrylic elastomer sheet filled with conductive ceramic material. The pad is moderately conformable, allowing it to fill surface gaps and improve thermal contact between mating surfaces.

Key Highlights

- UL94 V-0 listed

- Does not contain intentionally added silicone

- No siloxane VOC or oil bleeding associated with silicone products

- Good conformability, even on non-flat surfaces

- Soft, compliant material helps reduce high-pressure zones on components

- Good electrical insulation properties

- Good wetting performance for improved thermal conductivity

- Incorporates a thin acrylic layer for easy handling during pre-assembly and die-cutting

Thermal Performance

- Thermal Conductivity: 2.1 W/m·K

The material is designed to support consistent thermal transfer by filling interfacial gaps between components and heat sinks.

Material Characteristics

- Acrylic elastomer-based thermal interface pad

- Medium-soft consistency

- Single-layer construction

- Slightly tacky surface for placement stability

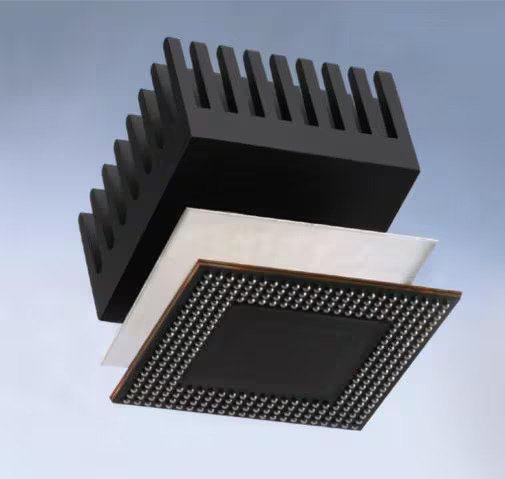

Purpose of Using a Thermal Pad with a Heat Sink

Thermal pads like 3M™ 5571 are used between heat-generating components and heat sinks to improve surface contact. They help fill air gaps caused by surface irregularities and support a more stable heat transfer path without the use of liquid or grease-based materials.

Thickness Selection for Heat Sink Use

Thickness selection depends on the gap size and surface flatness between the component and the heat sink. The selected thickness should allow proper contact without excessive compression. Final thickness choice should be confirmed through design evaluation or testing.

Thermal Pad vs Thermal Paste (General Comparison)

| Aspect | Thermal Pad | Thermal Paste |

| Form | Solid sheet | Semi-liquid |

| Thickness Control | Fixed | Variable |

| Handling | Clean and dry | Can be messy |

| Rework | Possible | Typically not reusable |

Typical Heat Sink Applications

The 3M™ 5571 thermal pad is suitable for use between heat-generating components and cooling devices in applications such as:

- Heat sinks and aluminum plates

- Electronic modules requiring thermal coupling

- EV battery thermal management systems

- Other electronic assemblies requiring thermal interface materials

Handling and Assembly Benefits

- Easy positioning due to slightly tacky surface

- Suitable for pre-assembly processes

- Compatible with die-cutting operations

- No curing or mixing required

Important Notes

- Follow 3M technical documentation during design and assembly

- Verify thickness selection before final installation

- Do not stack pads unless specified by design requirements

- Thermal performance depends on proper surface contact and assembly pressure

Reviews

There are no reviews yet.