Relays are basically switches that take up a small control current and use it to administer higher voltage loads. There are varieties of relays and they include General Purpose Relays, Power Relays, Miniature Relays, and PCB Power Relays. In this blog, we review typical failures witnessed with these relays and the best possible diagnostic strategies to ensure they serve safely.

Common Relay Problems and Their Solutions

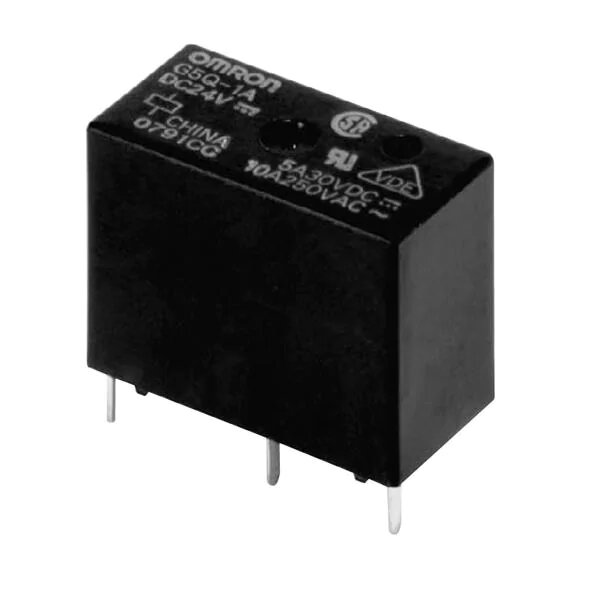

General Purpose Relays

General Purpose Relays are multipurpose and commonly found in several areas like automotive industry or home automation systems among others. They have the capability of switching various kinds of loads including resistive inductive capacitive loads among others.

Best Offer Available

Common Issues

- Contact Wear and Tear- As for the contacts in the general-purpose relays, the contact resistance may be upset because of the repeated switching or even cutting down their closing and opening exchangers.

- Failure of the Coil- The relay coil can burn due to overheating, high voltage, or continuous use. The relay will not actuate due to a bad coil.

Troubleshooting Tips

- Examine Contacts- Periodically inspect the pitting, burning, or oxidation of contacts. The contacts need to be cleaned or replaced.

- Measure Coil Resistance- Use a multimeter to measure coil resistance. Test the relay; if its resistance is much more or less than this value, change the relay.

Power Relays

Power relays are suitable for high-current and voltage applications, typically controlling motors or solenoids as well as lighting systems in homes, electrical equipment, etc.

Common Issues

- Heat: power relays that switch loads they are not rated for can cause them to overheat. If the relay gets too hot, it can seize the contacts, weld them, or bake out coil insulation.

- Mechanical Failure: Armature springs, etc., might become dislocated and worn out, leading to malfunctioning mechanical components inside the relay itself.

Troubleshooting Tips

- Check Load Ratings- Ensure the relay is rated for the load it is switching. Check load ratings.

- Examine mechanical parts– Adjust or replace parts as needed.

Miniature Relay

Miniaturized compact design suitable where space limitations exist, like telecommunication instrumentation control panels.

Common issues

- Insufficient Contact Pressure and small size, which leads to miniaturized relays having lower contact pressures, resulting in unreliable contacts and, hence, increased resistance due to poor connections made by them.

- Environmental factors– Include susceptibility to dust, moisture, and temperature fluctuations that impact performance, among other things.

Troubleshooting tips

- Increase Contact Pressure- If the relay in question has a design feature that allows it, then increase contact pressure, as this will enhance reliability.

- Protect from Environment- Use sealed containers with proper ventilation, but ensure humidity does not exceed operational limits.

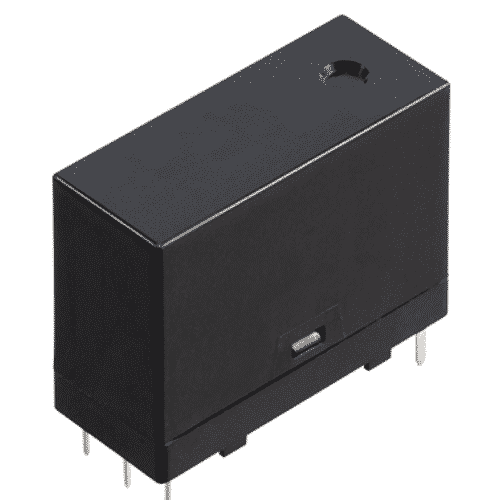

PCB Power Relay

Mounting the PCB power relay is done directly on printed circuit boards (PCBs) and finds application in numerous electronic devices like control systems, power supplies, and appliances.

Common Issues

- Solder Joint Failure- Thermal cycling, mechanical tension or poor soldering methods may result in solder joint failures in PCB power relays.

- Contamination of the Board- Presence of contaminants on the PCB such as dust, moisture or flux residues can impair performance of a relay.

Troubleshooting Tips

- Inspect Solder Joints- Search for very small voids in solder joints originated at the time of assembly of electronic components on PCBs, or any kind of cold solder joints. Resell if the products need to be refinishing or reflowed.

- Clean PCB- To enhance the relay performance, clean the board of contaminants causing short-circuiting with appropriate cleaning materials that will not harm the board.

Best Offer Available

PCB Mount Power Relays

PCB-mount power relays are basically similar to those meant for mounting on PCBs, but they differ slightly because their primary purpose is high-power applications where robust and dependable switching is needed.

Common Issues

- Thermal Control- Insufficient thermal control would cause the relays to overheat and get them into broken or prolonged usage, which gives them a short existence.

- Mechanical Stress- Mechanical stress can mean anything from bending the pins slightly to slamming a door on them. However, any deformation of the pin structure or other mechanical damage would likely cause your mount power relays to malfunction or be damaged (rotation angle).

Troubleshooting Tips

- Better Thermal Management- Include heat sinks, thermal vias, proper airflow, and other methods to help dissipate the amount of heat surrounded by devices. Similarly, check the running temperature to avoid heating it.

- Reduce mechanical stress: Do it gently when installing a board and relay. Also, appropriate mounting methods should be adopted to minimize the physical strain exerted upon them during usage.

Conclusion

Improving the reliability of electrical systems can be made easy by identifying problems in general-purpose relays, power relays, miniature relays, PCB power relays, and PCB mount power relays. This can be done by finding out what went wrong in the system, such as failure to start or intermittent operation, which includes overheating, contact welding, and insulation breakdown, among others. For proper performance of these devices, it is important to carry out regular maintenance on them while using them correctly so that they do not break down frequently, thus increasing their lifespan. The same applies when working with general-purpose relays or even smaller types, like miniaturized ones, but following different tips for each type will enable you to have reliable electrical systems.