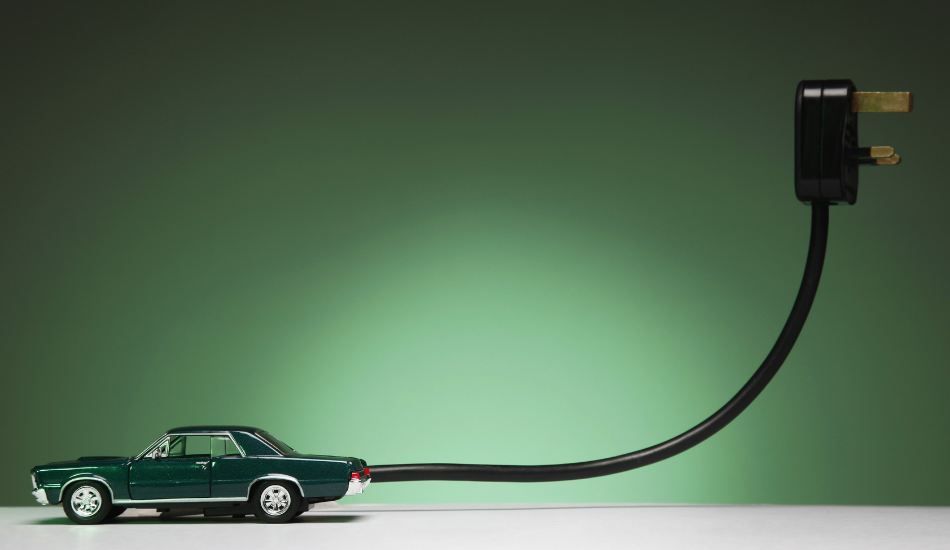

The EV battery connectors come in a variety of pins and other factors. Also, the connectors become the primary concern when working with battery chargers and charging stations. We have brought information about EV battery connector 2pin 100A and 4pins 10A battery pack assembly connectors.

What Is The Main Purpose Of Ev Battery Connectors?

The primary purpose of an EV battery connector is to join electric circuits. Therefore, most battery packs require more than one connector. There are several types of connectors, such as mechanical and electrical. Both have interfaces for batteries or other electronic devices.

Features that can be the primary factor in the selection are operating temperature. The range and limit of connectors are also crucial for the batteries’ capacity. A suitable connector can withstand very high temperatures.

How To Choose The Right Ev Battery Connector?

Connectors that can work under extreme temperatures can prevent short circuits. Also, the battery pack assembly connectors have proper pins assignments. As a result, it increases the current and performance capacity. However, it also meets the short-circuit threshold that is predetermined.

The pin arrangements are designed to fit the device, so it is vital for better performance and capacity. In addition, charging will be tricky if the connection is not well between the cable and the device.

In the end, the EV battery pack connectors should be able to handle fluctuating temperature and current voltage. However, the ratio of the phase voltage and current has to be preset. In case otherwise, the expected connector will not work as it is supposed to.

The BMS battery pack is one of the most widely used connectors. It comes in a wide variety of pin arrangements cush as 2pin 100A and 4pins 10A battery pack assembly connectors. The current voltage is also shared as it is the most crucial element.

Several reasons pose challenges and concerns to the safety of the vehicle. The interchangeability of the connector also makes an impact. For example, 2pin 100A connector and 4pins 10A pack assembly connector.

Shop Now

3M Thermally Conductive Interface Pad 5590H

Request For Price

3M thermally conductive interface pad 5571

Request For Price

What Are The Different Types Of EV Connectors?

The EV battery connectors are exactly like the phone connectors. It also has two connectors, one that connects to the charging station and the other one to the socket in the vehicle.

The type of connector varies by vehicle and its requirement. Also, the power rating or speed will be a considerable factor. EVs have type 1 or type 2 sockets for charging.

The speed will vary as slow/fast charging and rapid charging. Slow and fast charging are mostly typed 2. Also, EV users and derives have portable charging cable which matches their vehicle and allows them to charge from public charging stations.

The EV charging connectors can withstand power from 11kW to 43kW. Unlike the 2-pin charger, a 3-pin plug can work at 10kW also.

Rugged and heavy-duty connectors should be able to work in harsh weather conditions and extreme temperatures. If you use an ordinary domestic charger, a simple short circuit can damage the wiring and the battery.

The EV connectors should be able to work like two communication. A pin plug is highly effective and can fulfill this.

What Are The Features Of A Good Ev Battery Connector?

1. It should be touch proof.

2. Also, the connectors should be compact yet robust capacity for current holding.

3. EMI shielding is also required from the connectors.

3. The ideal connectors also have a quick lock and press-to-release design for ease.

5. Rated current and rated voltage need to be checked.

6. The operating temperature range is between 20°C to +85°C.

7. Weight of the connector cable.

8. The point at which the connector connects with the electric vehicle

9. The shape of the connector

10. The complexity in the structure of the connector

11. The type of locking/anti-locking system required for the connector

12. RoHS compliant.

Conclusion

The EV battery connectors come in a vast variety of pin arrangements, and their voltage rating also has a range. Apart from this, there are more factors to consider before choosing a battery pack assembly connector.