Electrical Vehicle manufacturers are still using some of the relatively expensive components like batteries, contactors, and power electronics.

The electric vehicle or hybrid electric vehicles are not complete without high voltage fuses. There are several high voltage fuses types and each of them acts to provide safety to people and make. The EVs fast and practical to be used in life.

Switching to electric vehicles has come up as a sustainable way of transportation. Electric commercial vehicles are in very high demand, the supply chain industry is not able to function. And using older vehicles that run on fossil fuels adds to the cost and makes the whole operation more expensive.

The Eaton high voltage fuses are new in the market and they have arrived just at the right time making such crucial parts easy to procure and access for the completion of the manufacturing process.

The Eaton Bussmann EV fuses are introduced after a rigorous testing and designing process. The designs are made specially to suit the need for compact designs of cars and help them by keeping them lightweight. The Bussmann EV fuses are also much in demand as it does not compromise the quality and safety even if it is smaller and lighter. Bussmann EV fuses are in high demand because these enable fast-acting and fast charging as well.

Why are Eaton High Voltage Fuses Ideal in Modern EVs?

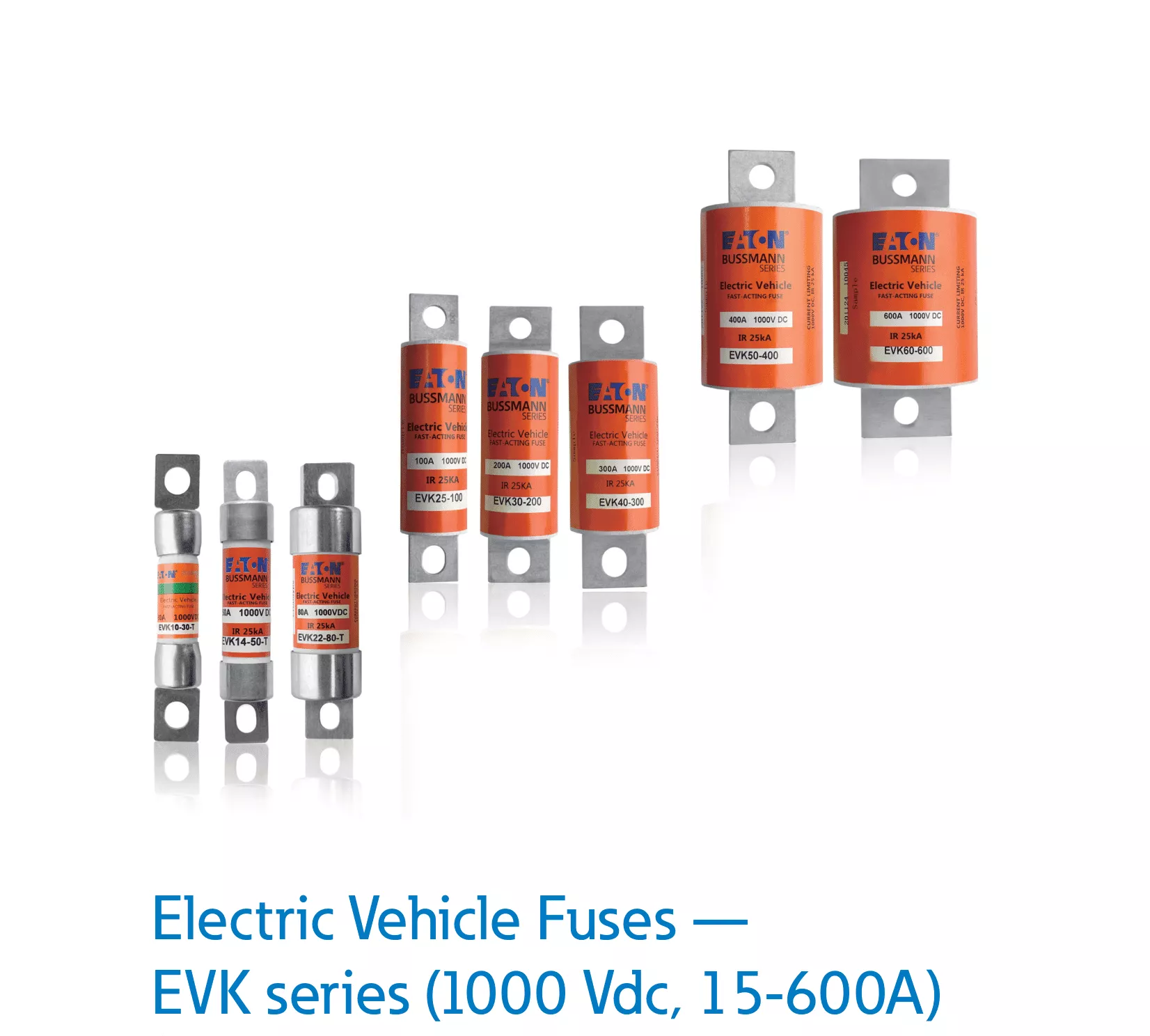

The Eaton Bussmann is focusing on EV fuses and it has come up with a variety of them in different amperes and current ratings. They have introduced some of the features that have never been included before in an EV fuse. The range of current and voltage they provide is outstanding making Bussmann EV fuses one of the most sought-after products in electric vehicle manufacturing.

The EVK series from Bussmann can withstand harsh working conditions and are one of the most rugged high-performing EVs.

The new and modern high voltage fuses types from Bussmann are designed by engineers to provide ample protection to the hyper-sensitive components of electric and hybrid automotive.

It also acts as the protector for several other sensitive parts and components like the high-capacity batteries and the power-conversion equipment. The contactors, cables, and other auxiliary circuits are also sensitive and need protection for function.

If we look at the Eaton high voltage fuses, we can see the safety concerns tackled by the electrical system of the car and the reduced costs related to damage and warranty of the components.

Eaton has provided the EV sector with a fuse that can easily withstand a wide range of overcurrent events. It does not get impacted due to the continuous working and cycles of fatigue attributed to the heavy use.

In addition, the fuses are engineered with a 20 kA interrupting rating to enable a longer vehicle range by protecting higher capacity and more efficient batteries with higher fault currents. For more information

What Are the Characteristics of Eaton High Voltage Fuse?

The manufacturing and designing unit of Eaton is providing an outstanding range of high voltage fuses types and their characteristics are also having a bigger span in current rating and capacity. Let’s see some of these points to be clearer about their invincibility.

Current Rating & Current Carrying Capacity of Fuse

The rating of current refers to the capacity of current flow at any given time. The EV fuse requires carrying a huge amount of current to the main controlling unit and the amount of power can impact the performance of your vehicle if not supplied in the required amount or lesser than that.

Voltage Rating

It is referred to as the capacity to withstand the type of current and its amount when the vehicle is plugged into the charging station. The upper limit of the current rating would be the highest amount of current that the fuse can take safely without damage and failing. hat

The above-mentioned points come with only one goal and that is to provide enough safety so that the vehicle can perform fine without posing a security and safety threat either to the person or to the parts and components in close vicinity.

But there can be more to the EV fuses than just being present for safety! There are other benefits also and some advantages as well that only come with high voltage fuses. Let’s take some of the benefits.

What are the Advantages and Benefits of Using High Voltage Fuses?

There is more to the fuses that protect the components, let’s see some of The fuses are successful alternatives to the traditional equipment and these come with high precision as well.

These are quite sturdy and rugged so one does not need to worry about their ambient working conditions and temperature. These can work perfectly fine even in extreme weather conditions.

We have already mentioned the capacity of current flow and current amperes. The interrupting capacity of Bussmann EV fuses has a range up to 1000 VDC and amperes go up to 600.

These are also fine working with the charging stations and systems in the vehicles to provide a lifetime of reliable performance in high-capacity commercial and passenger vehicles.

Another benefit that only comes with Bussmann fuses is the compact size and lightweight. Both help in making the end product more desirable and aesthetically pleasing.

The Bussmann series EV fuses act as a guard against the issues of circuits and components by dissipating the heat from the areas that are more sensitive compared to others. Overheating can be dangerous to the battery of the vehicle.

If the battery pack is overheating it is considered the most high level of threat in any electric vehicle and some recent stories of EVs catching fire in the middle of charging or even road. The level of protection Eaton high voltage fuses provide is impeccable and should not be seen lightly in comparison with others.

These are some of the benefits and advantages but it is not always the case. We are still facing some issues and challenges, let’s quickly go through them one by one and cover some of the EV fuse challenges faced by the EV manufacturers.

What are the Challenges of Electric Vehicle Fuses?

With the emergence of the electric vehicle, other needs are emerging as well. There are issues regarding the compatibility and industry-level standardization of the components so people do not face issues in the future when visiting the mechanics.

We are referring to the differences between industry-level high voltage fuses types and others. Some of the primacy concerns are as follows:

Ambient Environment for Application

The general and older versions of fuses are based on alternate current, however. The modern fuses are more compatible to work fine in direct current application situations.

Cyclic Load

The previous generation of fuses was unable to predict the load they can take on and this was the problem that affected the start/stop and driving of the car to define the load.

Appropriate Temperature

The high voltage fuses types especially the ones that are meant to work in high-performing and rugged working environments are more susceptible.

Shock and Vibration

The fuses should be able to withstand higher shock and mechanical vibration. The modern fuses can work fine even in this situation due to their sturdiness and strength.

Space and Weight

The Eaton high voltage fuse and other automotive fuses need installation to be right as these are nothing more. Then calibrated devices that transfer the high load of current from one place to another.

The structure is also robust as there are other components as well in the close vicinity to complete the whole segment of the device. Some fillers like silica sand are also there in the shape of an arc. The silica sand is present due to its ability to provide heat resistance to ceramics. The installation type and style might be different in some cases but the overall structure of the EV fuse remains the same in every setting.

The fuse performance is based on several items like the filling material i.e., silica sand, processing quality, and configuration. The most dominating current material used in EV fuses is silver. Also, the shape can be diverse as well as ribbon and filament to some extent. The shapes and cross-section will positively impact the character of that fuse.

Another shell body material of fuses is epoxy fiber tube and it has high bending strength without breaking and it is also quite inexpensive.

The normal conditions are when the fuse just carries the current to some location. But when extreme conditions appear like overcurrent. In this situation, the heat generation is faster than the fuse can transfer. If this overcurrent situation stays for longer than normal. The fuse material reaches its highest level of temperature which is the melting point and the fuse will break.

The speed of fuse melting is related to the higher amount of heat. The fuse has an inverse time-current characteristic. Which is also an ideal characteristic for protecting conductors and electrical equipment. Let’s see other lesser-known facts about this.

Does Replacing the Damaged Car Fuses help?

If something is off or not working as it normally should in usual conditions. You can either replace it on your own or take it to the mechanic. He will change it for you. But is there always a replacement? Not quite.

If you have replaced the fuse once and the replacement also blows promptly. Then changing it is not the answer here.

The first figure out the root cause of the issue as just the replacement will not work. In this situation, the mechanic will be the right answer.

Can Someone Replace the Fuse on Their Own?

Anyone with a basic understanding then does not run off to the mechanic as changing the fuse is quite simple and easy. You can follow our guide to identify the fuse and replace it by going through the following:

Always test this beforehand by using another device to the plugin that is working fine.

Find out the type of fuse used already as there are many types of fuses. If you have the blade fuse then you just need to push it. If you see a glass fuse just align the metal contacts with the tube and then push it into the fuse box.

Avoid using tools to remove or place the fuse. It can react with the contact metal and can affect the fuse.

Always remember that raising the current voltage of the fuse is not the solution. The whole electric system and circuit of the vehicle are done to support the fuse and vice versa.

Conclusion

In an ideal situation, the electric system of an electric vehicle should never fail. The various high voltage fuses types are there to ensure this. However, the electrical system and circuits can never be guaranteed to be fail-proof.

And when this happens, the wiring will not be able to handle the sudden increase in the current flow. It will cause overheating and melting of the fuse and insulation. If the situation gets out of hand, it can cause a fire.

The Eaton high voltage fuse prevents these bad things from happening. The Bussmann EV fuses series protects against high amperage in the circuit, before the wire breaks.