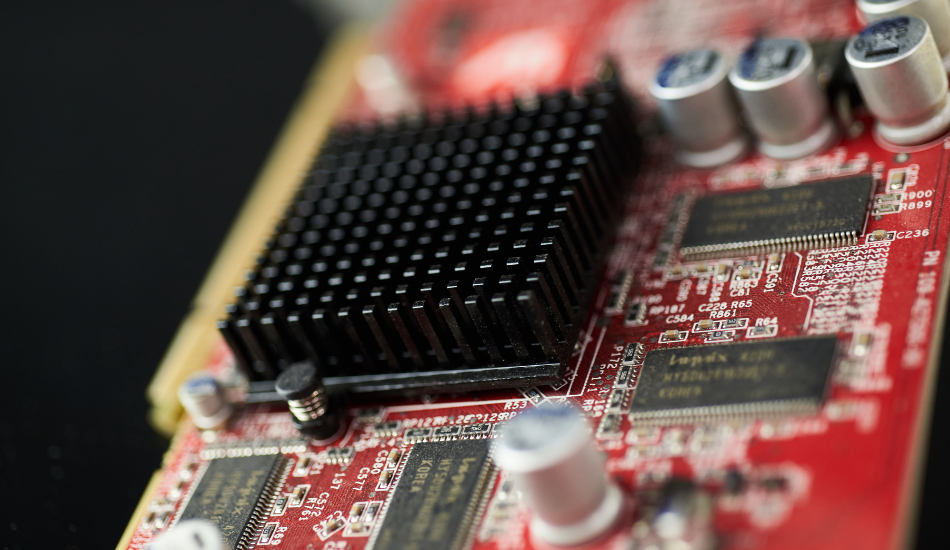

The engineers and designers have always been looking for more options for thermal adhesives to stick heatsinks with heat generating components. Heat sink attachment is necessary, but there is more to this than slapping the heatsink and returning to work.

In this part, we cover thermal tape, epoxy, thermal paste, and other variations of thermal adhesive to stick heat sink.

Common Thermal Adhesives for Heatsinks

Thermal Epoxy

Thermal epoxy is a solution or mixture of two materials with different elements and features. It is either a single or dual-part mixed adhesive with thermally conductive fillers such as silver. It provides outstanding mechanical adhesion strength.

It is also effective with copper heat sinks and will not move off the semiconductors. It’s also an inexpensive thermal adhesive to stick heat sink; however, it costs a bit more than tape.

For the epoxy to work well, it must first be refrigerated. Then, it should be applied skillfully so that you don’t put on too much or too little. It should be applied in a uniform layer throughout the heatsink.

It works in two ways being applied uniformly; this material secures the heat sink and acts as a thermal interface material. The thermal interface will conduct the heat from semiconductors to the heat sink.

First, the surface needs to be prepared and cleaned using epoxy adhesive. Then the layer should be spread in a uniform layer. Also, remember that it leaves a residue if it is removed. For rework, the residue is not ideal.

It is a glue that leaves residue if removed after some time. The best way to remove the residue is to loosen it through heating using a heat gun or thermal welder.

Shop Now

3M Thermally Conductive Interface Pad 5590H

Request For Price

3M thermally conductive interface pad 5571

Request For Price

How to Use it For the Best Results?

To ensure the most beneficial adhesive bond between the digital devices and the heatsink, the surfaces of the elements to be bonded need to preferably be dry and clean from dirt and grease.

In particular, care needs to be taken to eliminate lines of thermal conduction paste or residue on plastic housings, which could save you dependable bonding. When using the thermal adhesive, it’s advised to put on safety gloves and use a lint-free cotton cloth. The perfect processing temperature degrees among 20-28°C.

Once you’ve got your elements ready, use a small quantity of the adhesive on one of the surfaces to be bonded. Then, observe a thin layer of an activator to the opposite floor to be bonded.

Slightly flip the elements to be bonded together and be part of through pressing firmly for a few minutes. If you notice the need for changes, important corrections to the placement of the elements should be made within 15-30 seconds of bonding before the material gets dry and hardened.

After bonding the 2 surfaces, wait five min for the adhesive bond to be secure. The bond could have reached about 70% of its last electricity at this time. After 24 hours, the bond may be cured and could have reached 100% very last electricity. Any extra adhesive that accumulates at the rims may be effortlessly eliminated at this time.

Thermal Tape

Thermal tapes are pressure-sensitive adhesives. These come in various forms and materials, generally acrylic. The primary benefits generally are easy to attach, and it is also quite inexpensive relatively. It is one of the best options available for the lowest cost approach for aluminum heat sink attachment.

You can use thermal tapes for heavy heatsinks for bigger areas. Some 3M thermally conductive tapes come with high and industrial-grade bonding strength, making them suitable for such heatsinks. However, thermal interface tapes generally have moderate to low conductivity.

Some thermal tapes include a carrier, while others encompass an adhesive that is eliminated from a liner previous to application.

Like different TIMs, thermally conductive tapes are designed to transfer heat from a heat-generating component to a heat sink. These specialized tapes help die cut and conform nicely to surfaces that aren’t flawlessly flat.

Die-cut thermal tapes are transformed from huge or standard-size rolls. These are available in multiple sizes and thicknesses. Their traits consist of excessive mechanical electricity and tremendous performance.

How to Use Thermal Tapes

Thermal tapes are very easy to use and involve a less complicated process. As we already mentioned, you can avail it in different sizes and thicknesses, so there is no need to worry about a uniform layer.

You can also ask them for a specific shape or size as a die-cut. Next, peel the lining off the double-sided thermal tape and stick it to the surface. Then remove the other layer of liner and stick the other part to it.

Then gently press down both surfaces together; remember that the tapes are pressure sensitive, unlike epoxy materials. You can hold it for a few seconds, and the surfaces will bond perfectly.

Types of Thermal Tapes

3M designs and provides the best quality thermal tapes. 3M thermally conductive adhesive transfer tapes are perfect for thin bonding applications.

3M provides four varieties of thermal tapes 8805, 8810, 8815, and 8820. Each die-cut tape gives dielectric electricity and applies fast and effortlessly.

3M thermally conductive adhesive tapes present low thermal resistance and advanced thermal conductivity. These double-sided tapes provide sturdy adhesion to low-floor power substrates.

Application of Thermal Adhesive to Stick Heat Sink

Thermal tapes are used with LED lighting, electronics, and batteries. These die-cut tapes help flex bonding and offer heat conduction for integrated circuits (IC).

Often, thermal tapes are used with cooling devices, including fans, heat spreaders, and heatsinks. Because they’re soft, those adhesive tapes can also offer dampness and cushioning.

Thermally conductive adhesive tapes eliminate steel or metal fasteners such as rivets and screws in LED applications. Instead of attaching LED lights to a heat sink with a screw and screwdriver, assemblers can peel and stick die-cut thermal tapes instead.

This saves time in product assembling and elongates the lifecycle of the LED by moving heat away from the supply.

Conclusion

Although heat sinks are a vital part of our computers and other electronic devices, many people still don’t understand why we need thermal adhesive to stick heat sinks. In the most effective of terms, a heat sink is an item that disperses heat from every other item. But it needs to be attached for it to do the work.

Used in digital structures as a passive heat exchanger, a heat sink has a thermal conductor that transfers heat away from the heat-generating components. Designers and engineers use thermal adhesives to stick heatsinks with heat-generating components.

While the most common device can be a computer, heat sinks are also used in smartphones, LED lights, or refrigerators.

Find Die Cut Thermal Tapes

E Control Devices is an authorized distribution partner of 3M and provides these tapes in precision die-cut form. We also can supply, convert, and die-cut thermal tapes from 3M. We also assist with material suggestions and value-delivered offerings, including technical assistance. To know more, contact our technical assistance team.