Do you have challenges in keeping your batteries in good shape and health? Do your batteries keep on failing in a short time, or their performance reduce over time?

All you need is a battery management system to improve your batteries’ overall health and enhance their performance. But there are several aspects of BMS, like moisture protection and thermal management, which we will be discussing in a different section.

What Is Battery Management?

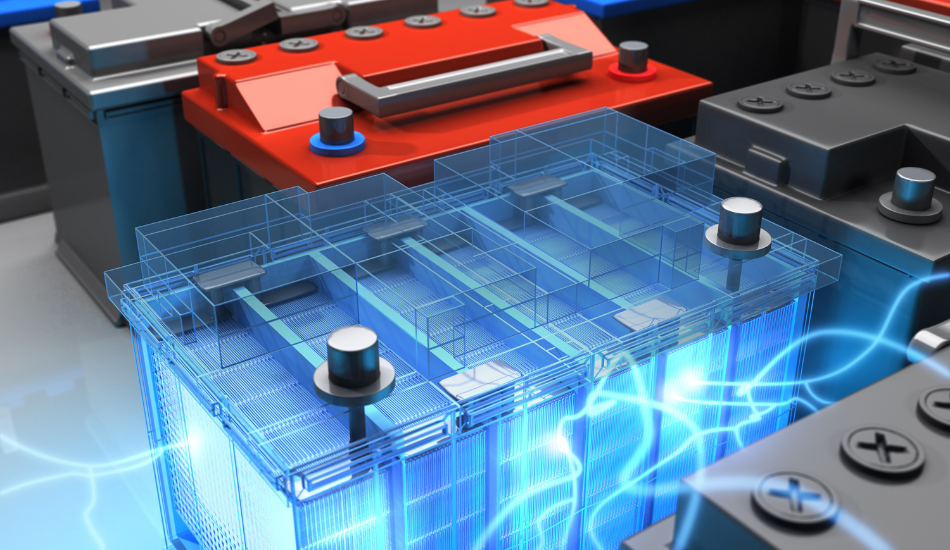

A BMS or battery management system is a combination of features and methods for the safekeeping of the batteries. It is required to meet the battery packs’ safety and operational necessities.

The BMS also takes care of the battery’s state of charge.

The SOC keeps the battery in a predefined range and keeps monitoring for any change in the state of health of the battery. Its work also involves protecting high voltage current and fluctuation in the temperature.

Shop Now

3M Thermally Conductive Interface Pad 5590H

Request For Price

3M thermally conductive interface pad 5571

Request For Price

How Does Battery Management System Work?

The battery is not a single unit; instead, it is made of numerous cells, which are then packed together, called the battery pack. Each cell requires effective thermal management, so it doesn’t generate excessive heat. It also requires an effective battery management system that will help keep its performance stable and safe.

The BMS monitors each cell in the battery pack and keeps an eye on the SOC and SOH. This provides insight into the current requirements for safe charging and discharging action.

The limit of the current acts as the cut-off and helps prevent the overcharging issue. The cells inside the battery packs can be damaged due to high currents and fluctuations.

Why Is BMS Important?

BMS is the key to lithium-ion batteries’ safe, reliable, and efficient performance. It also ensures the effective functioning of the battery. BMS provides an overall electric supervisory to manage each cell’s parameters. Irrespective of the voltage and amount of current, all batteries require BMS.

Several methods and topologies available in the market are used in different types of BMS methods. There are centralized and decentralized categories then there are some other types of topologies for off-the-shelf battery management systems.

Batteries have different characteristics to monitor, such as battery type, voltage, charging cycle, temperature, capacity, state of charge, operating time, and many other crucial aspects.

The BMS ensures the usage of residual power in the battery and protects batteries against deep discharge to avoid loading. Extremely fast charging and high discharge rate are responsible for overvoltage, which must be avoided.

The BMS is responsible for mainly 6 components: battery cell monitoring, CutoffFET, temperature monitoring, cell voltage balance, BMS algorithm, and Real-time clock.

BMS is the primary command for performing crucial operations in a battery pack. It enables various functions and provides fault detection too. Voltage, current, and temperature control are done efficiently. The BMS is also responsible for passive cell balancing and data storage. Successful SOH and SOC are other aspects of BMS.

What Are The Industries That Require BMS?

Every device using a rechargeable battery requires BMS, and it is also a very common aspect of daily operations in the data center. Data centers require universal power supplies for the servers’ constant and stable power supply.

For example, you can take smartphones or portable devices like music players. These devices run on rechargeable batteries requiring BMS. Other big industries are automotive, service robots, wearables, home appliances, and power tools.

What Is The Scope Of BMS?

The batteries face several issues, including thermal runaway, excessive heat generation, and other environmental issues that can arise from moisture and dirt buildup in the battery pack.

There are dedicated technologies for controlling thermal runaways and thermal management in the battery, but other aspects, like moisture and dirt, still threaten the battery’s performance.

The design engineers and manufacturers have been using coatings for moisture protection. The coating provides ample safety against such environmental elements.

3M Novec 2704 coating is one such product that can be used in any battery, and it will protect the battery cells from moisture and dirt. Companies are investing in these products to ensure the quality of their products and provide safety to their consumers.

If you are looking for any such solution, E Control Devices is the right platform for you as they have the expertise in providing such products per the application and the process. 3 M authorizes them as their official channel and distribution partner. They maintain the largest range of 3M engineering-grade fluids, such as 3M Novec 2704 coating and other liquids.

You can find 3M Novec 2704 coating on www.econtroldevices.com or connect with them for more information or any other requirement.